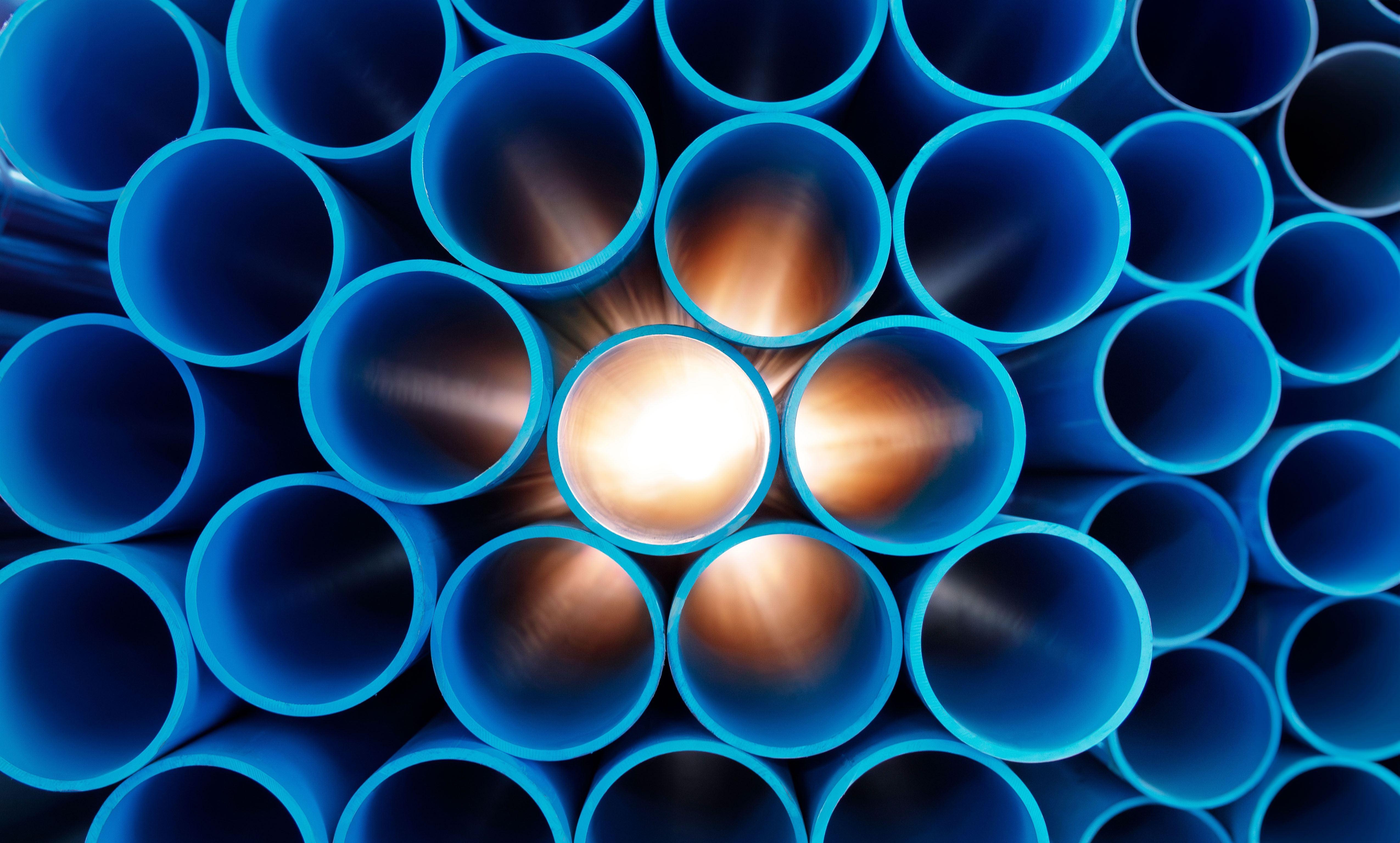

Smart Performance MES at Uponor– Digital Pipe Production with AVEVA InTouch and AVEVA Historian

Uponor continuously improves production efficiency and quality by using the Smart-Performance MES solution developed by Klinkmann Group's MI team (Machine Intelligence) on the AVEVA InTouch and Historian (System Platform) software platforms. The goal is data-driven, quickly responsive production. The objective of injection molding production is smooth, high-quality operation.

Uponor's injection molding production must be quickly controllable. Production batches must be planned and scheduled flexibly. Real-time data collection and comprehensive production reporting were set as the goals of the chosen production control solution when starting a project with Klinkmann.

Uponor's operations in Finland consist of the development and manufacturing of building technology and community technology products. Uponor's customers include professionals in the infrastructure and HVAC sectors as well as consumers through its partners. The group has 3,500 employees and an annual turnover of €1.5 billion.

Data-driven production - improvement in productivity and fewer production disturbances

The conceptualization and piloting of the project was done quickly by Klinkmann's MI team ((Machine Intelligence).

With the standard platform, the application is easy to scale to the desired extent and maintain, as well as continuously adapt to changing needs, says Harri Mikkola, Production Manager for Injection Molding Production at Uponor.

In data-driven production, operations can be based on real-time information, without errors in judgment and decision delays.

Klinkmann solution:

- AVEVA InTouch and Historian (System Platform) software provide a standard platform to which production data collection and various automation and IT systems can be easily connected.

- Smart-Performance MES (by Klinkmann) offers ready-made dashboard reports and displays as well as analysis tools for the collected production data.

Benefits for the customer:

- Real-time view of the production situation

- Real-time production reporting

- Monitoring and reporting of disturbances in real-time

- Monitoring of operating rates per machine

- Monitoring of waste per product

- Predictability of product changes

Uponor

Uponor started production in Nastola in 1965 under the name Upo-Muovi. Uponor develops water-related solutions for the benefit of future generations. Products and services for safe water distribution, energy-efficient heating and cooling, and reliable community technology enable a more sustainable living environment.

The conceptualization and piloting of the project was done quickly by Klinkmann. With the standard platform, the application is easy to scale to the desired extent and maintain, as well as continuously adapt to changing need.